PNEUMATIK

- Home

- PNEUMATIK

Aluminium Composite Piping System

for Compressed Air, Vacuum, Inert Gases,

Chilled Water and Industrail Water Systems

Pneumatik Multilayer Composite Pipe is an innovative, next generation thermoplastic pneumatic piping system which combines the advantages of its metal and thermo-plastic materials and at the same time eliminates the disadvantages associated with these materials.

Pneumatik Multilayer Composite Pipe is the latest innovation in piping systems being the ideal choice for Compressed Air, Vacuum, Inert Gases, Chilled Water and Industrial Water systems. It is manufactured as per the latestInternational standards

and adhere to stringent quality control procedures resulting in a world class product.

Pneumatik Multilayer Composite Pipe have many benefits such as – light weight, bendability and no need to weld, glue or thread. Itis also economical when compared to traditional piping systems such as Aluminium and Galvanized Iron. The installation time is significantly reduced compared to the traditional pipes leading to increased productivity and further reduction in the overall costs of the piping system.

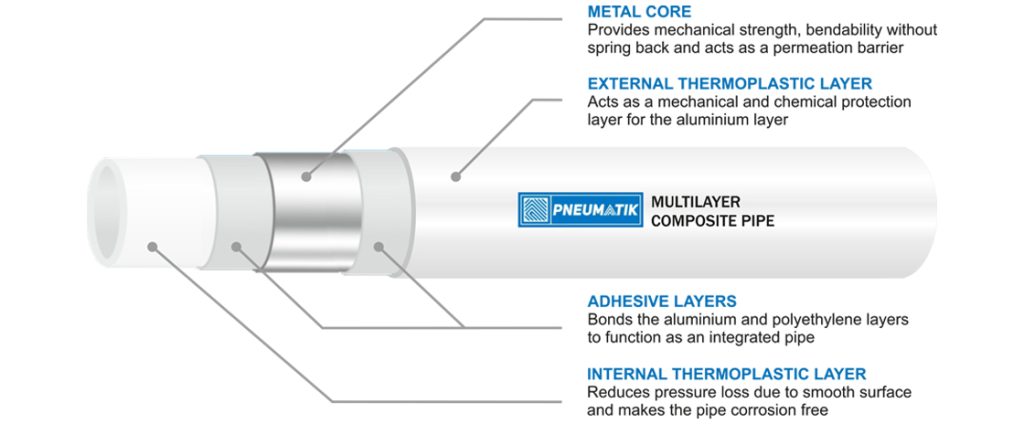

Pneumatik Pipe is made up of multiple layers. The inner layer is made of thermoplastic, with a cental core of Metal, then covered by an outer Thermoplastic layer. Between the metal and thermoplastic layers are the bonding adhesive layers.

As a result of this unique combination of materials, the product is such that allows excellent properties to be reached that otherwise would not be possible in a pipe made from any single material – metal or thermoplastic.

ADVANTEGES

- Long Service life – of atleast 50 years.

- Bendability – pipes can be bent manually by hand, without springing back to its original shape.

- Minimum Fittings – use of elbows and couplers is reduced by upto 95% due to bendability and long length of pipe coil.

- Simple installation – quick and clean installation with only basic tools, no welding, solvent cement or thread cutting required.

- Leak free – our compression fittings feature unique double O-ring seals to ensure long term joint integrity and aleak free piping system.

- Permeation barrier layer – the metal core acts as a permanent barrier to the passage of alien substances.

- Thermal linear expansion – upto 9 times less compared to plastic pipes and similar to that of metal pipes.

- Light weight – 1/3rd weight compared to copper pipes and 1/10th of steel pipes.

- Corrosion resistance – Pipes have total resistance to corrosion and construction materials.

- Minimum pressure loss – minimum friction due to a smooth inner surface.

PRODUCT RANGE – PIPES

| Material | Thermoplastic with Metal core |

| Color |

Outer Layer - White Inner Layer - Natural |

| Application |

Compressed Air Vacuum Inert Gases Chilled Water Industrial Water |

| Operating Pressure |

232 psi (16.0 bar) @ 23°C 175 psi (12.0 bar) @ 60°C |

| Operating Temperature | -20°C to 60°C |

| Standard Coil Length | 1620 - 200 mtrs., 2025 - 100 mtrs. & 2632 - 100 mtrs. |

MULTILAYER COMPOSITE PIPE

| Size | Size (inches) | Pipe ID | Pipe OD |

|---|---|---|---|

| 1620 | ¾" | 16 mm | 20 mm |

| 2025 | 1" | 20 mm | 25 mm |

| 2632 | 1¼" | 26 mm | 32 mm |

BRASS CONNECT FITTING

All our fittings are manufactured using the best manufacturing processes and high quality extruded & forged.

EQUAL UNION

UNEQUAL UNION

FEMALE UNION

MALE UNION

| SIZE |

|---|

| 1620 x 1620 |

| 2025 x 2025 |

| 2632 x 2632 |

| SIZE |

|---|

| 2025 x 1620 |

| 2632 x 1620 |

| 2632 x 2025 |

| SIZE | SIZE |

|---|---|

| 1620 x 1/2" | 2025 x 1" |

| 1620 x 3/4" | 2632 x 3/4" |

| 1620 x 1" | 2632 x 1" |

| 2025 x 1/2" | 2632 x 1.1/4" |

| 2025 x 3/4" |

| SIZE | SIZE |

|---|---|

| 1620 x 1/2" | 2025 x 1" |

| 1620 x 3/4" | 2632 x 3/4" |

| 1620 x 1" | 2632 x 1" |

| 2025 x 1/2" | 2632 x 1.1/4" |

| 2025 x 3/4" | 2632 x 1.1/2" |

EQUAL ELBOW

FEMALE ELBOW

MALE ELBOW

EQUAL TEE

| SIZE |

|---|

| 1620 x 1620 |

| 2025 x 2025 |

| 2632 x 2632 |

| SIZE | SIZE |

|---|---|

| 1620 x 1/2" | 2025 x 1" |

| 1620 x 3/4" | 2632 x 1" |

| 2025 x 1/2" | 2632 x 1.1/4" |

| SIZE |

|---|

| 1620 x 1/2" |

| 2025 x 1" |

| SIZE |

|---|

| 1620 x 1620 x 1620 |

| 2025 x 2025 x 2025 |

| 2632 x 2632 x 2632 |

UNEQUAL TEE

FEMALE TEE

MALE TEE

PIPE END

| SIZE |

|---|

| 2025 x 1620 x 2025 |

| 2632 x 1620 x 2632 |

| 2632 x 2025 x 2632 |

| SIZE |

|---|

| 1620 x 1/2" x 1620 |

| 2025 x 1/2" x 2025 |

| 2632 x 1/2" x 2632 |

| 2632 x 1" x 2632 |

| SIZE |

|---|

| 1620 x 1/2" x 1620 |

| SIZE |

|---|

| 1620 |

| 2025 |

| 2632 |

Size 3240 & 4050 multilayer Composite pipes & brass fittings are also available

INSTALLATION PROCEDURE

Pneumatik Multilayer Composite Pipes should always be installed using P-Matik Brass Connect fittings and Pneumatik Installation tools for best performance and applicability of Warranty. It is also important to follow each of the below steps for successful installations.

Step 1: Cut Pneumatik Multilayer Composite Pipes at 90′ angle

Step 2: Insert Nut and Split Ring onto Pipe.

Step 3: Round & Chamfer the Pipe (3-5 rotations).

Step 4: Insert Fitting and Tighten Nut with Spanner to Complete Jointing.

Pipe Bending: Bend Pipe Using Internal / External Bending Springs

PRODUCT WARRANTY

Pneumatik Fluid Distribution products are manufactured using the best raw materials, latest processes and as per international product standards.

We provide a 15 years warranty on pipes & fittings against any manufacturing defect subject to the following Terms and Conditions:

- Warranty is applicable only when Pneumatik Multilayer Pipes and P-Matik Brass Connect fittings are used together in combination . Warranty will be void in case of use with pipes or fittings of other brands.

- Pneumatik Installation procedure is followed and Pneumatik Tools are used for installation.

- Pneumatik Fluid Distribution system is used within the defined Operating pressures and temperatures .

- AHPPL provides free replacement of faulty products under this warranty and is not liable for any other costs incurred directly or indirectly.

- Thewarranty does not cover faulty workmanship .

PIPE REAMER

PIPE CUTTER