Pneumsys

- Home

- Pneumsys

Authorized Dealer of Pneumsys | Proficient in Turnkey Projects & Installation

COMPANY PROFILE

Pneumsys, the perfect example of productivity and adaptability, serves as a reliable solution for a multitude of applications, including compressed air, vacuum, inert gas, process water, and chemical transfers.

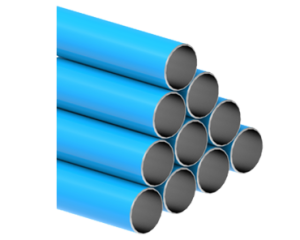

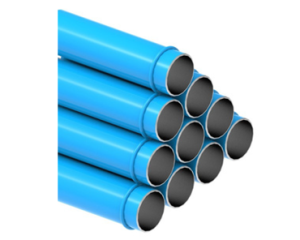

Pneumsys aluminium pipes come with a mirror finish on the inside, thus ensuring laminar flows. The unmatched finish on the inside is a protective layer to ensure no oxidation of the inside of the pipe when exposed to water, oil, or all other contaminants, so the media flowing through the pipe remains integral in nature. This is in stark contrast to conventional materials like black iron or copper, which are known to deteriorate over time just because of corrosion. Pneumsys consistently provides pristine air quality while maintaining peak flow rate performance, in perfect harmony with our commitment to energy efficiency and sustainable product design.

Our Certifications

PRODUCT QUALITY

ISO Certification

Pneumsys Connectors manufacturing facilities are certified ISO 9001 version 2015 and operate a Quality Management System in order to ensure the level of quality and service thatis expected by the customer.

Qualicoat Certification

All aluminum pipes are coated with a lacquered powder coated finish with a Qualicoat certified coating for additional environmental protection. PRESSURE VESSEL REQUIREMENTS.

ASME B31.1/B31.3 Conformity

Pneumsys meets the requirements of ASME B31.1 & B31.3 which stipulates "the minimum requirements for the design, materials, fabrication, erection, test and inspection of power and auxiliary piping systems for industrial institutional plants" as non boiler external piping.”

SAFETY STANDARDS

Pneumsys meets standards for safety, quality & compliance as specified for process piping.

ENVIRONMENTAL PROTECTION

ISO 14001

MSYS is ISO 14001 certified for our Environmental Management System, which requires a plan to reduce the environmental impact on manufacturing and selling products.

REACH - RoHS

AUll MSYS products comply with the REACH and RoHS directives which limit the use of hazardous substances.

Recyclable

All Pneumsys products are 100% recyclable.

MEDIA QUALITY

ISO 232021 Certification

ISO 8573 is the international standard for compressed air quality. Pneumsys products have been tested to meet the highest air quality standard found within ISO 8573. The air quality is dependent on the treatment performed in the compressor room. Pneumsys will not introduce additional solid particles, water, moisture, or oil into the media being conveyed.

Oil Free Certificate

Pneumsys products will not contaminate the conveyed media with grease or oil products.

LONG TERM COMMITMENT

10 Year Warranty

Pneumsys warrants its products to be free of manufacturing defects in material and workmanship to be used for oil free and moisture free compressed air for 10 years from the date of installation.

Field of Application

| SOME TECHNICAL CHARACTERISTICS | |

|---|---|

| Standard Colour | RAL 5012 |

| Max Working Pressure | 16 BARS |

| Plant Testing Pressure (1 Hour at 20°C) | 24 BARS |

| Quality Testing Pressure (1 Hour at 20°C) | 64 BARS |

| Production Tested Percentage | 100% |

| O-ring | NBR 65/75 S.A. |

| Continuous Service Temp. Limit | -20°C to 100°C |

| Aluminium Pipe Mechanical | According to EN-755-2/2008 |

| Pipe Material | Aluminium Alloy EN AW-T5 (External Treatment: Powder Coating, Internal Treatment: Chromatizing) |

| Internal Treatment | Chromatized |

| Fittings Material | Aluminium |

| Teeth Ring Material | 304 Stainless Steel |

| Threads Standards | ISO 7-1:1994(en) |

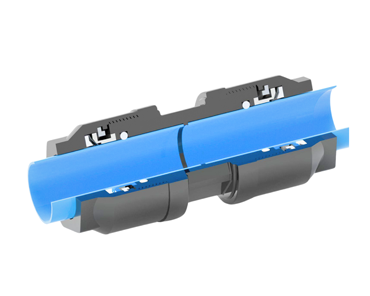

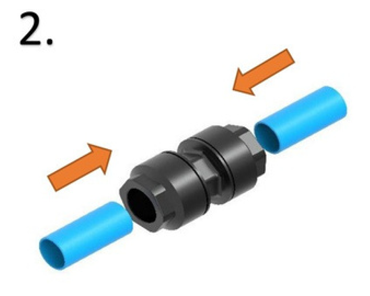

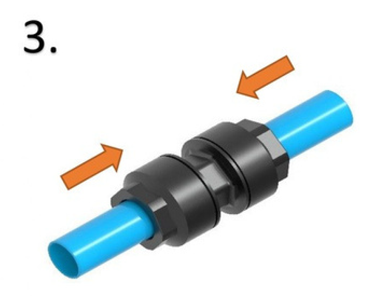

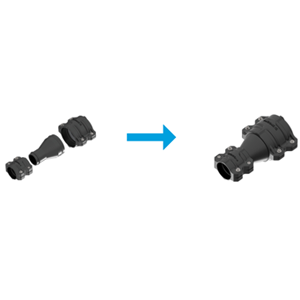

Push-Fit Range

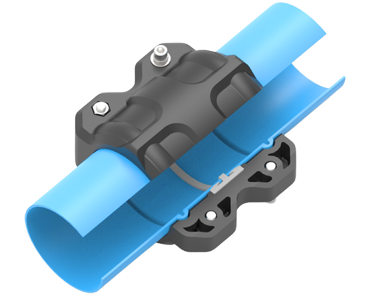

Pneumsys Push-In Fitting has a 100% aluminium and an integral design that has the O ring housed securely in the body of the fitting, so there is no chance of it getting dislodged during assembly/disassembly/misaligned during assembly.

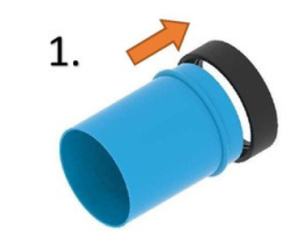

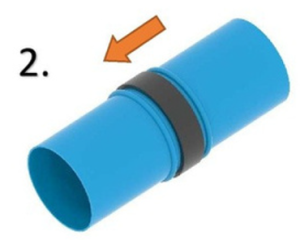

Assembly Instructions For Push-In Fitting

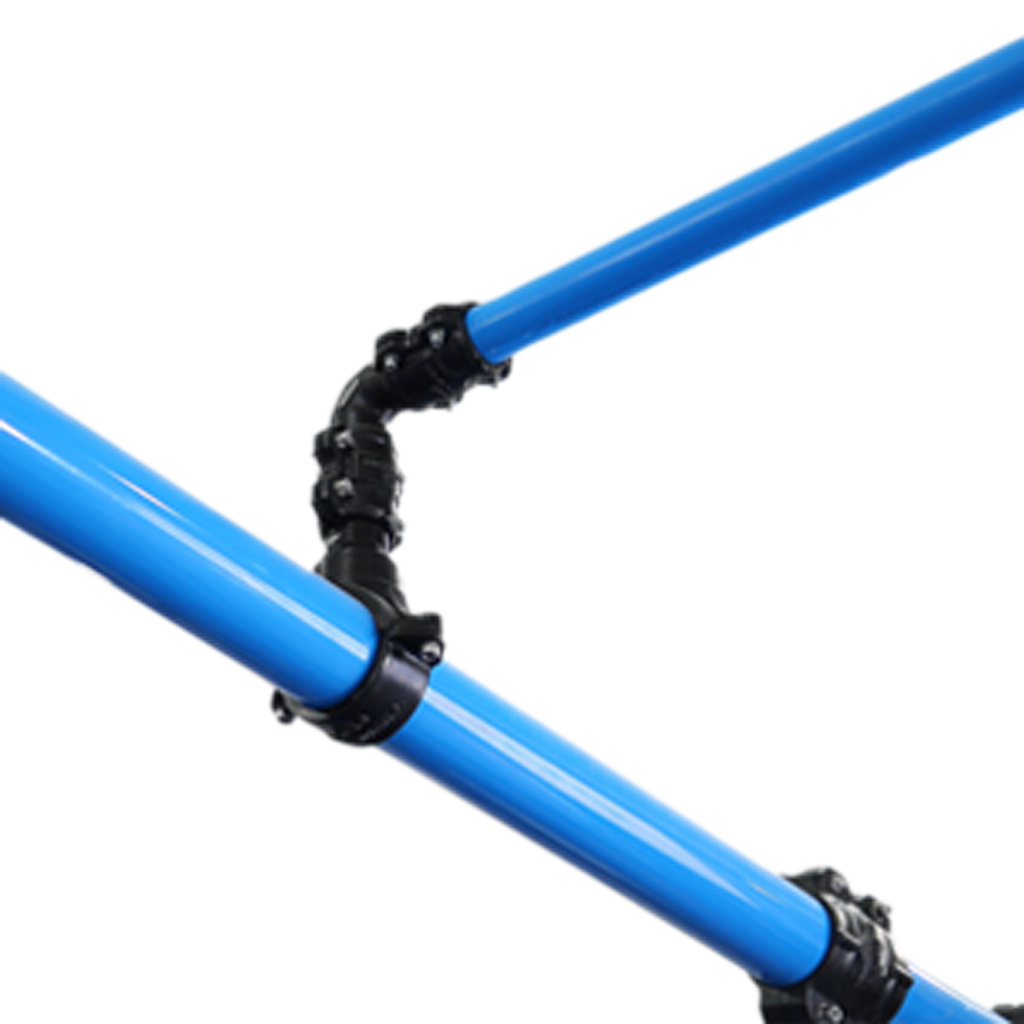

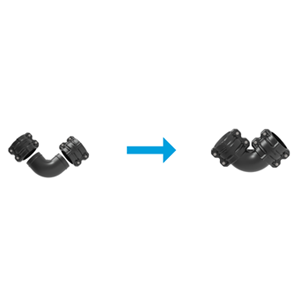

Groove-Fit Range

Pneumsys Groove coupling and push-in fittings are manufactured from 100% aluminium, and test reports can be given for the same. The couplings are having superior cataphoresis coating to ensure 100% resistance to any effect due to weather conditions.

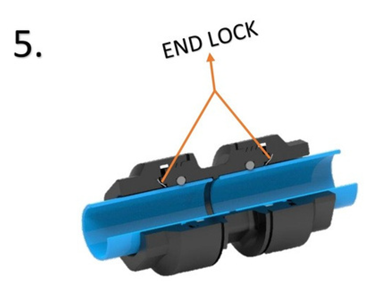

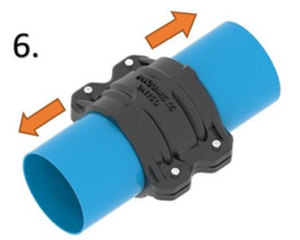

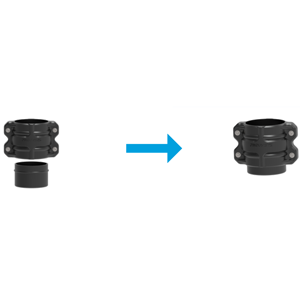

Assembly Instructions For Groove Fitting

Groove Fitting Connection With Groove Connector

NOTE : For pipes required with grooved ends to be used with grooved couplings, the above model is to be used with “-G” added as a suffix at the end of the model number.

| REDUCING STRAIGHT CONNECTOR | |

|---|---|

| PART NO. | SIZE |

| PNRSC5020 | 50 X 20 |

| PNRSC5025 | 50 X 25 |

| PNRSC5040 | 50 X 40 |

| PNRSC6325 | 63 X 25 |

| PNRSC6340 | 63 X 40 |

| PNRSC6350 | 63 X 50 |

| PNRSC9050 | 90 X 50 |

| REDUCING STRAIGHT CONNECTOR | |

|---|---|

| PART NO. | SIZE |

| PNRSC9063 | 90 X 63 |

| PNRSC10050 | 100 X 50 |

| PNRSC10063 | 100 X 63 |

| PNRSC10090 | 100 X 90 |

| PNRSC150100 | 150 X 100 |

| PNRSC200100* | 200 X 100 |

| PNRSC250100 | 250 X 100 |

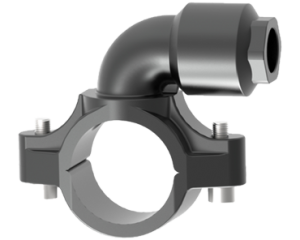

| SADDLE BRANCH | |

|---|---|

| PART NO. | SIZE |

| PNSB2212 | 22 X 1/2″ |

| PNSB2512 | 25 X 1/2″ |

| PNSB2812 | 28 X 1/2″ |

| PNSB3212 | 32 X 1/2″ |

| PNSB4012 | 40 X 1/2″ |

| PNSB4034 | 40 X 3/4″ |

| PNSB5012 | 50 X 1/2″ |

| PNSB5034 | 50 X 3/4″ |

| PNSB5001 | 50 X 1″ |

| PNSB6312 | 63 X 1/2″ |

| PNSB6334 | 63 X 3/4″ |

| PNSB6301 | 63 X 1″ |

| PNSB7501 | 75 X 1″ |

| SADDLE BRANCH | |

|---|---|

| PART NO. | SIZE |

| PNSB7502 | 75 X 2″ |

| PNSB9001 | 90 X 1″ |

| PNSB9002 | 90 X 2″ |

| PNSB10001 | 100 X 1″ |

| PNSB10002 | 100 X 2″ |

| PNSB11001 | 110 X 1″ |

| PNSB11002 | 110 X 2″ |

| PNSB15001 | 150 X 1″ |

| PNSB15002 | 150 X 2″ |

| PNSB15003 | 150 X 3″ |

| PNSB25002 | 200 X 2″ |

| PNSB25003 | 250 X 3″ |

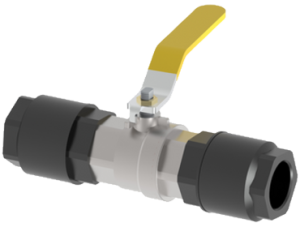

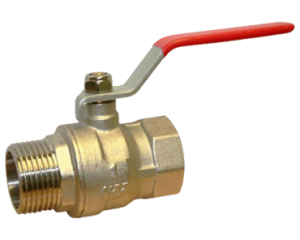

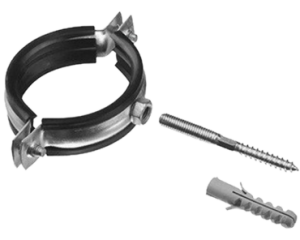

Accessories Range

Accessories are critical components used in conjunction with pipe fittings to secure, support, and stabilize piping systems in various industrial, commercial, and residential applications. These accessories ensure that pipes remain firmly in place and are safely routed through different structures.