Asian compressor

- Home

- Asian compressor

Authorized Dealer of Asian Equipments | Spares and Service Available

COMPANY PROFILE

It is based in Pune & Satara, Maharashtra, at Om Sai Group Company. Our range of machines includes screw compressors, vertical air receivers, refrigeration dryers, line filters, and auto drain valves. All these are authorized to international quality standards & are wisely acknowledged for their sturdy design & durable finish standards. We are authorized with a powerful infrastructure that is well-equipped with ultra-modern equipment and machines. Our rich business acumen, coupled with a clear vision & exceptional management skills, has helped us to win the trust of many leading companies & brands in a very limited time.

‘ASIAN AIR COMPRESSOR’ is one of the leading compressor suppliers in India.

‘Every industry deserves to be furnished with the best compressed air solutions in the world’ to successfully enhance their efficiency. ASIAN AIR COMPRESSOR used the opportunity & has come a long way by accomplishing the customer’s needs. All our customers tag ASIAN AIR COMPRESSOR as a trusted brand to satisfy their compressed air needs.

Our happy customers are widespread & have robust support over our offerings. Asian Air Compressors have empowered various industries & have also touched people’s lives as compressed air solution providers. Be it the tires of your vehicles, the paint you see on aesthetic products, or the medicines you carry, somewhere or the other

ASIAN AIR COMPRESSOR has worked effectively under non-standard pressure & extreme ambient conditions. Our market is widespread across India through our local dealer network & OEM, who work tirelessly in providing the best customer satisfaction experience.

ASIAN COMPRESSORS

| SM- FIX SPEED AIR COMPRESSOR | |||

|---|---|---|---|

| HP | PRESSURE | CFM | AIR OUTLET |

| 7.5 HP | 7/8/10 | 35/30/26 | G 3/4” |

| 10 HP | 7/8/10 | 44/40/37 | G 3/4” |

| 15 HP | 7/8/10 | 68/64/59 | G 1” |

| 20 HP | 7/8/10 | 85/80/78 | G 1” |

| 25 HP | 7/8/10 | 116/108/100 | G 1” |

| 30 HP | 7/8/10 | 135/122/110 | G 1” |

| 40 HP | 7/8/10 | 182/174/160 | G 1*1/2” |

| 50 HP | 7/8/10 | 240/225/209 | G 1*1/2” |

| 60 HP | 7/8/10 | 275/249/240 | G 1*1/2” |

| 75 HP | 7/8/10 | 374/310/270 | G 2” |

| 100 HP | 7/8/10 | 485/418/356 | G 2” |

| SMV- VARIABLE FREQUENCY DRIVE AIR COMPRESSOR | |||

|---|---|---|---|

| HP | PRESSURE | CFM | AIR OUTLET |

| 7.5 HP | 7/8/10 | 35/30/26 | G 3/4” |

| 10 HP | 7/8/10 | 44/40/37 | G 3/4” |

| 15 HP | 7/8/10 | 68/64/59 | G 1” |

| 20 HP | 7/8/10 | 85/80/78 | G 1” |

| 25 HP | 7/8/10 | 116/108/100 | G 1” |

| 30 HP | 7/8/10 | 135/122/110 | G 1” |

| 40 HP | 7/8/10 | 182/174/160 | G 1*1/2” |

| 50 HP | 7/8/10 | 240/225/209 | G 1*1/2” |

| 60 HP | 7/8/10 | 275/249/240 | G 1*1/2” |

| 75 HP | 7/8/10 | 374/310/270 | G 2” |

| 100 HP | 7/8/10 | 485/418/356 | G 2” |

| ASN- TWO STAGE COMPRESSOR | |||

|---|---|---|---|

| HP | PRESSURE | CFM | AIR OUTLET |

| 30 HP | 7.2/10 | 146/128 | G 1” |

| 50 HP | 7.2/10 | 272/243 | G 1*1/2” |

| 60 HP | 7.2/10 | 371/314 | G 1*1/2” |

| 75 HP | 7.2/10 | 455/390 | G 2” |

| 100 HP | 7.2/10 | 602/495 | G 2” |

| 120 HP | 7.2/10 | 710/621 | G 2” |

| 150 HP | 7.2/10 | 840/721 | G 2” |

| 175 HP | 7.2/10 | 993/871 | G 2” |

| 215 HP | 7.2/10 | 1179/1078 | G 2” |

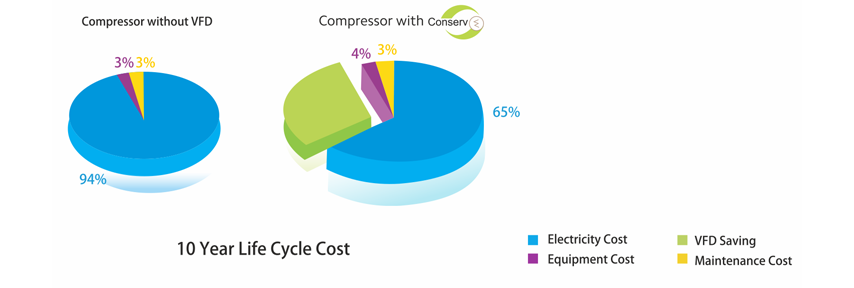

Energy Saving- The Conserve Way

Integral ASIAN COMPRESSOR Variable Frequency Drives (VFD) match compressor output with requirements by changing motor speed. The power usage decreases in line with the reduction in demand. Helps in reducing the persistent load-unload cycle & also the wasted power from the energy bill.

A constant-speed compressor easily works on a load-unload band of almost 10 psi around the heavy pressure; on the other hand, with the help of VFD, the specific compressor can be operated in almost a band of 2 psi.

Since the compressor is not worked under higher than working pressure needs, there is significant energy saving. For every 2 psi, there is scaling down in operating pressure. There is a 1% power saving.

In any constant-speed compressor with the help of a star-delta starter, beginning current is 3x higher than the full load current or FLC. With VFD, starting current is a lot less than FLC. This helps to prevent utilizing heavily rated components such as fuses, MCCBs, cable size, isolators, etc.

For most compressed air systems with varying demand patterns, giving a quick return on investment.

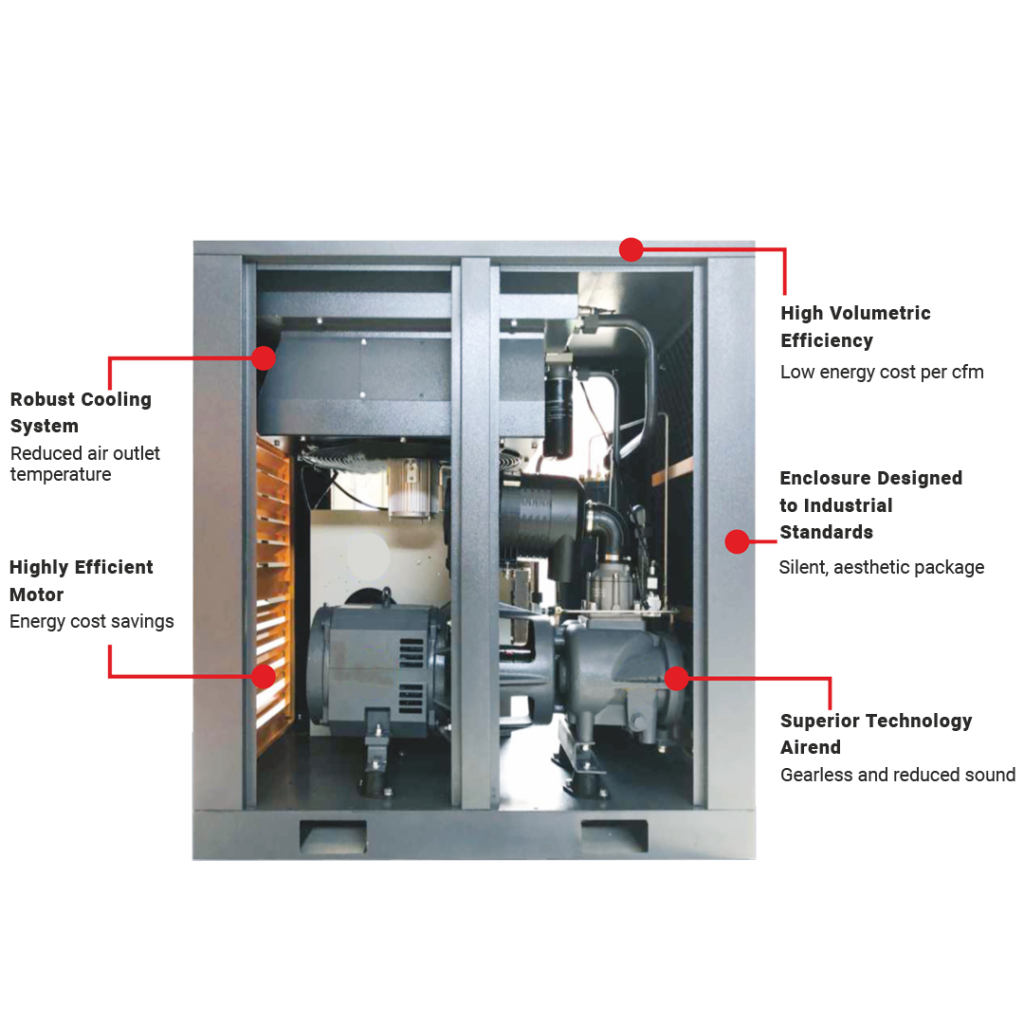

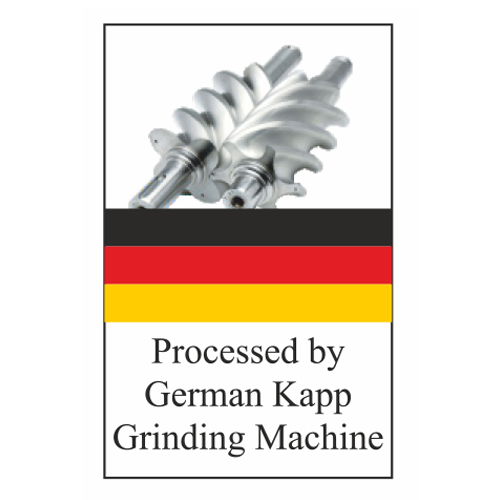

HIGHLY EFFICIENT AIR END

The air end uses the advanced asymmetric line and 5.6 profile rotor, the seal technology upgradation from line type to band type, which increases the production of air by almost 5% to 10%. Big rotor diameter & low rotation speed make sure the air end has a long life span & low noise.

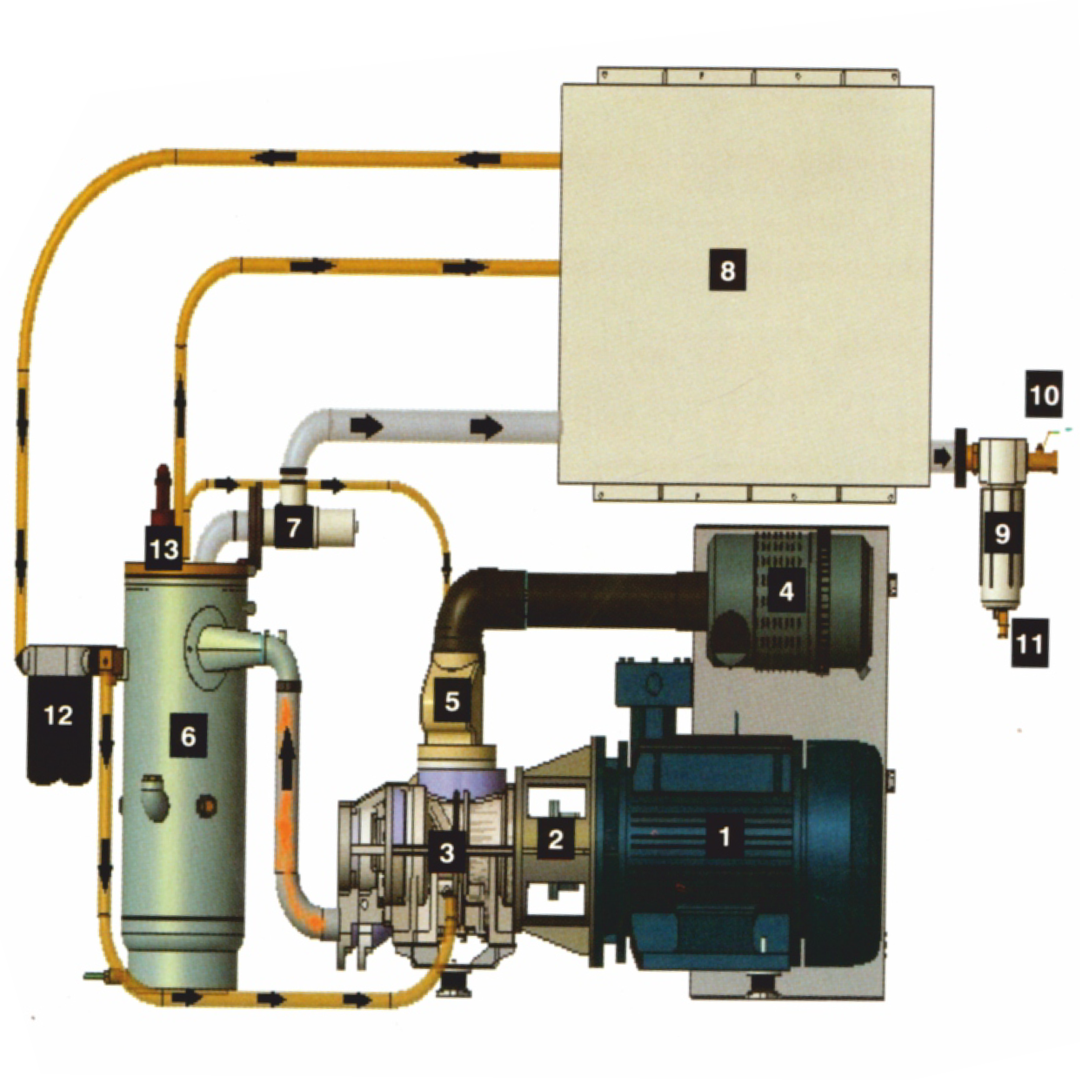

AIR/OIL FLOW DIAGRAM

AFTER SALES AND SUPPORT SERVICES

As good and efficient as our products are, equally excellent are our spare parts, along with our maintenance services that we offer through our offices and dealer network. Our dealer network and team of technicians are well equipped to handle all after-sales and support requirements for our product across India. We suggest utilizing original spare parts for the chosen compressors. The spares are usually supplied in pre-packaged kits for every item of a specific type of model and maintenance process.

Vision & Mission

The company is continuously working on compressed air technology beyond innovation by giving

- ● More Power Saving

- ● Intelligence Compressor Controller

- ● Smart Synchronizing System

- ● Zero Breakdowns

- ● Local and remote-operated system

- ● One Touch/Call Service System

After Market Support

At Asian, we believe in an extended relationship with our customers far beyond the sale of the product. We support both the product and its maintenance during its whole lifespan. Our worldwide supplier’s & OEM’s network supports the maintenance of our products.

Training is offered at the customer site location after commissioning of our reliable compressor system. According to the contract with customers, our client training center conducts several seminars and workshops for the client representatives at our head office.